There are seven main types and more than 20 subtypes of 3D printing technologies used around the world today. Each type has its own strengths, applications, and materials, making 3D printing one of the most versatile technologies in modern manufacturing.

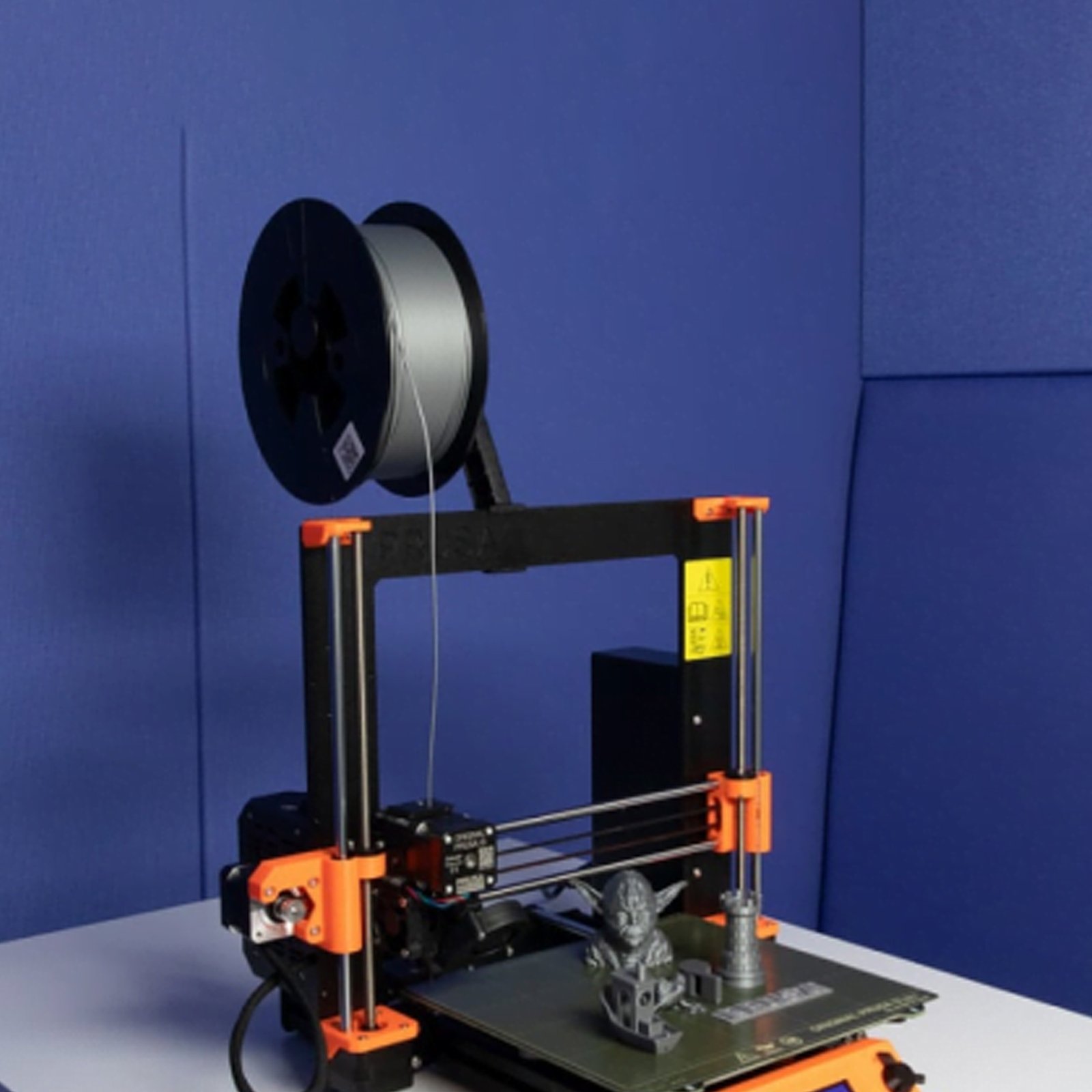

- Fused Deposition Modeling (FDM)

This is the most common and affordable type of 3D printing. It works by melting plastic filament and depositing it layer by layer. FDM is popular for beginners, hobbyists, and educational use. - Stereolithography (SLA)

SLA uses a laser to cure liquid resin into solid layers. It produces highly detailed and smooth models, making it perfect for jewelry, dentistry, and prototyping. - Digital Light Processing (DLP)

Similar to SLA, but it uses a digital projector to cure resin all at once instead of layer by layer. DLP is faster and widely used for small, precise objects. - Selective Laser Sintering (SLS)

SLS uses a laser to fuse powdered material—usually nylon—into solid parts. It doesn’t require support structures, making it ideal for complex industrial designs. - Selective Laser Melting (SLM) / Direct Metal Laser Sintering (DMLS)

These technologies work with metal powders, creating strong, fully functional metal parts. They are used in aerospace, automotive, and medical industries. - Material Jetting (MJ)

This method sprays liquid material onto a surface and cures it with UV light. It allows full-color printing and very fine details. - Binder Jetting

In this process, a liquid binder is sprayed onto layers of powder, creating objects that are later hardened. It’s commonly used for sand, ceramics, or even food-based printing.

Each of these types has its unique advantages, whether it’s cost, speed, strength, or level of detail. The choice of 3D printer depends on the purpose—educational, artistic, industrial, or medical. As the technology continues to evolve, new variations are emerging, making 3D printing more accessible and powerful than ever before.